Now Offering the Complete Line of Victory Energy Equipment for all of California and Nevada

WATERTUBE BOILERS

Powerhouse Mechanical & Combustion Corporation proudly offers all Victory Energy Watertube Boilers.

Victory Energy manufactures a full line of industrial watertube boilers. Suited for all industrial and institutional applications. We have hundreds of watertube boilers in operation worldwide bringing the latest innovations that deliver the most efficient steam boilers on the market.

No application is too small or too large. We thrive in an atmosphere of innovative thinking and breakthrough methodology. We carry this attitude forward from “Concept to Completion” as we work closely with our customers, in-house engineering teams, in-house project management teams, fabrication personnel, manufacturing crews, logistics department and field technicians.

In addition to providing rock-solid solutions that are reliable and compliant with the most stringent technical requirements, we are constantly looking for ways to maximize the efficiencies and value of total integration for our customers and end users.

Quality materials and superior construction are essential to producing industrial-duty boiler systems that are, by design, engineered to be the most reliable boilers in the world. Our approach to modularization is designed to maximize shop assembly while minimizing costly field labor and delivery time.

From permanent full-scale installations to temporary mobile systems, Victory Energy offers custom-engineered solutions for all types of applications in all kinds of industries including Petroleum, Utility/Power, Textiles/Pulp & Paper, Chemical Processing, Process Waste Heat, Institutional, District Heating, Ethanol, Oil Sands/Enhanced Oil Recovery and Thermal Solar projects.

O-TYPE WATERTUBE

The Victory Energy VOYAGER® O-type industrial watertube boiler is designed to provide a rapid ramp rate and is easy to ship, install, operate and maintain. These versatile, robust boilers have become very popular for applications that are extremely demanding in harsh environments.

Its symmetrical configuration is ideally suited for restrictive floor plans, while the gas outlet allows the addition of an enhanced heat recovery system in a vertical configuration to maintain the most efficient overall footprint.

Steam capacities rage from 10,000 PPH up to 500,000 PPH, design pressures from 250 PSIG to 2,000 PSIG with saturated and superheat temperatures up to 1,050 degrees F. Superheated versions are designed to minimize the steam temperature fluctuations across the operating range of the boiler.

Each VOYAGER O-type industrial watertube boiler is custom engineered with constructability in mind.

CAPACITIES

- Up to 500,000+ PPH

- Pressures range up to 2,000 PSIG

- Temperatures up to 1,050˚F

- Saturated or superheated steam

- Ideal for restrictive floor plans

D-TYPE WATERTUBE

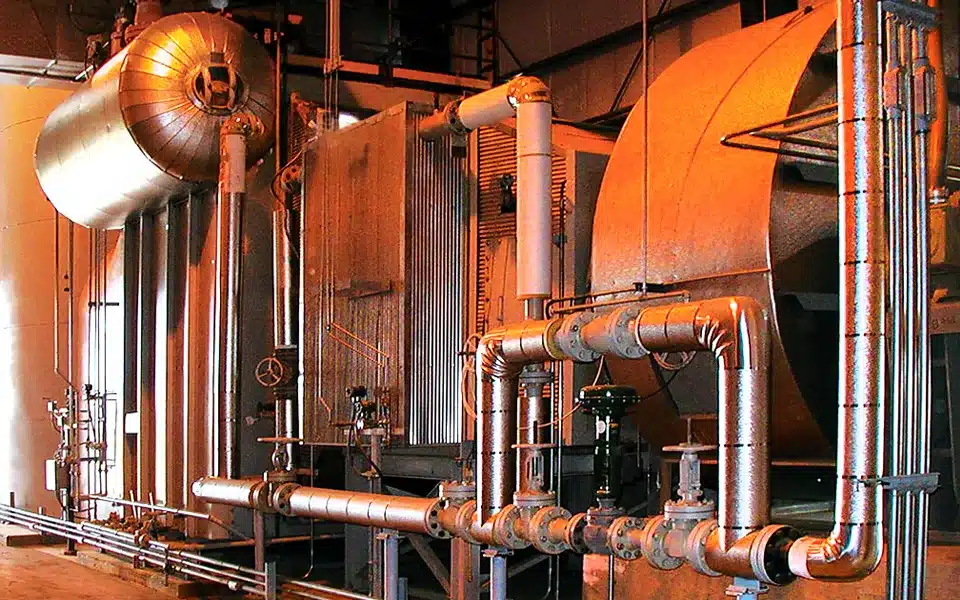

Victory Energy’s DISCOVERY® D-type industrial watertube boilers are operating in hundreds of industrial applications in a multitude of industries worldwide. This proven design offers large furnaces and are engineered for long-term reliability and are well suited for high-pressure superheated steam applications with restrictive heights.

Units range well in excess of 500,000 PPH. Modular and field-erected sizes are available as well as customized solutions including elevated/remote steam drum configurations. Convective style superheaters are desired when fuels are heavily laden with ash and superheat is required. All superheaters are placed within the boiler’s convective zone to eliminating exposure to the radiant energy in the furnace and ensures a long and reliable operating life. This conservative approach reduces harmful emissions.

CAPACITIES

- Up to 500,000+ PPH

- Pressures range up to 2,000 PSIG

- Temperatures up to 1,050˚F

- Saturated or Superheated steam

- Ideal for large capacities and modular configurations

A-TYPE WATERTUBE

Victory Energy VOYAGER® A-type industrial watertube boilers are designed to provide a rapid ramp rate and are easy to ship, install, operate and maintain. These versatile, robust boilers have become very popular for applications that are extremely demanding in harsh environments.

Its symmetrical configuration is ideally suited for restrictive floor plans, while the gas outlet allows the addition of an enhanced heat recovery system in a vertical configuration to maintain the most efficient overall footprint.

Superheated versions are designed to minimize the steam temperature fluctuations across the operating range of the boiler.

CAPACITIES

- Up to 500,000+ PPH

- Pressures range up to 2,000 PSIG

- Temperatures up to 1,050˚F

- Saturated or superheated steam

WHB WATERTUBE

Victory Energy offers a wide variety of HORIZON® Series watertube boiler solutions for a multitude of heat recovery applications, whether the need is hot water, steam (saturated or superheated) or high temperature thermal fluid.

No matter if the flue gas is clean or contains ash, whether its derived from a process in which the heat would otherwise be wasted or it comes from a purpose built combustion or gasification system that requires steam to generate power, Victory Energy has the solution.

Victory Energy’s proprietary modeling tools allow for the optimal finned tube design for the production of boilers to fit into small footprints which helps greatly reduce radiant heat losses, all without the compromising reliability

CAPACITIES

- Up to 500,000+ PPH

- Pressures range up to 2,000 PSIG

- Temperatures up to 1,200˚F

- Custom Engineered and Modularized

Firetube Boilers

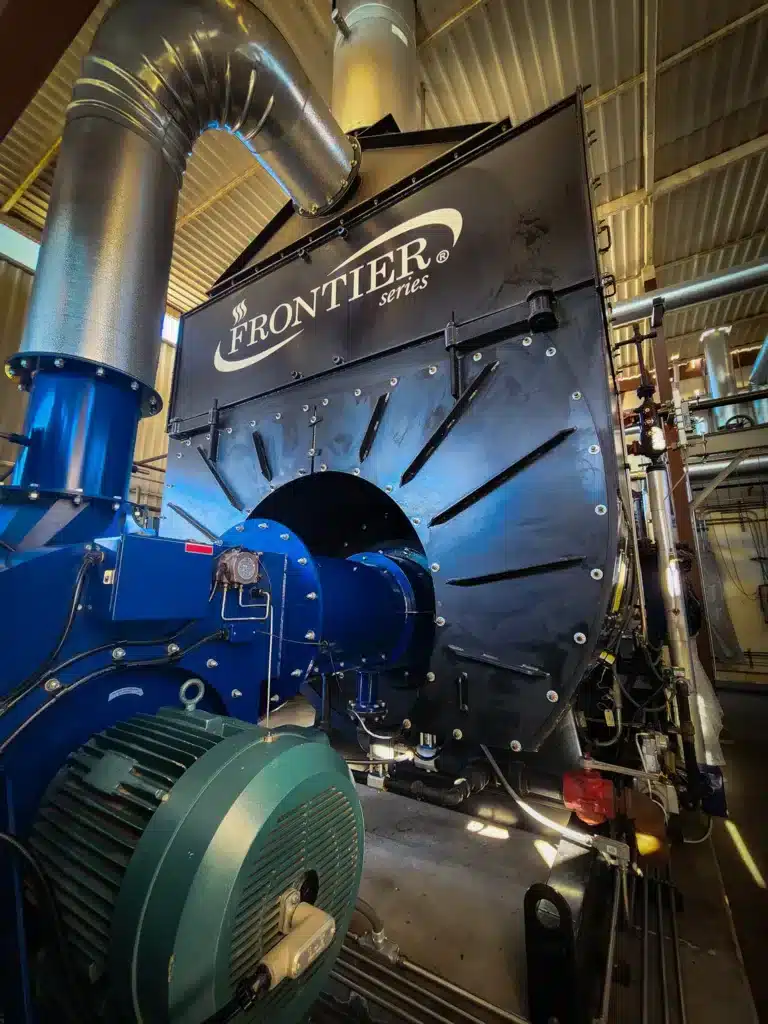

Powerhouse Mechanical & Combustion Corporation proudly offers the Victory Energy exclusive Frontier Firetube Boiler Line. Victory's team of engineers have designed a best in class line of firetube boilers. The key features offered standard on their boilers make the choice a no brainer. The design, craftmanship, and technology of these lines, represented and installed by Powerhouse, present quality and performance second to none.

From a dedicated manufacturing facility through to producing a full line of engineered wetback and dryback firetube boilers, Victory Energy is all in with FRONTIER® firetube boilers! Backed by the best-in-class distributors that sell and service our Firetube product offering, Victory has made a concerted effort to be the best manufacturer of firetube boilers that create maximum customer value.

Every FRONTIER® Firetube boiler is produced in an atmosphere of innovative thinking a breakthrough methodology. They carry this attitude forward from “Concept to Completion” working closely with customers, in-house engineering teams, in-house project management teams, fabrication personnel, manufacturing crews, logistics department and field technicians. Victory Energy controls the quality and timeliness on all project engagements to ensure that the product arrives on time and on budget.

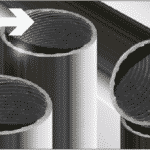

Victory Energy Firetube boilers are available in 2-, 3-, or 4-pass, wetback or dryback design. Further maximize efficiency with an integral EXPLORER® economizer for a complete package.

WETBACK FIRETUBE BOILERS

Victory Energy manufactures an extensive line of FRONTIER® Series Wetback firetube boilers that are available in 2-pass, 3-pass and 4-pass product configurations – ranging from 100 BHP to 2,500 BHP. Each boiler is engineered to exacting standards and built for minimum maintenance while maximizing output, efficiency and durability.

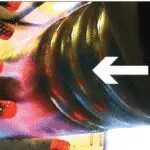

They feature water-cooled turnaround section, incorporates rifle tubes and include heavy duty skid construction to enhance performance in rugged duty applications. Burners are factory mounted and totally wired with state-of the-art controls.

CAPACITIES

- 2, 3 and 4-pass designs

- Up to 2,500 hp

- Fully Integral Economizers Available

KEY FEATURES

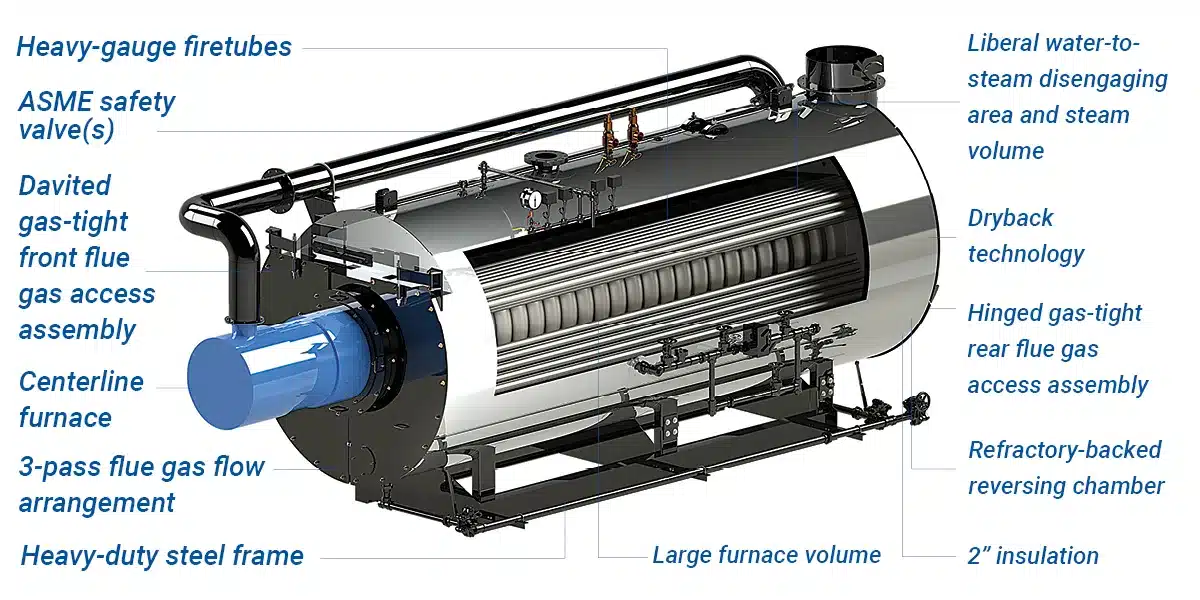

DRYBACK FIRETUBE BOILERS

Every FRONTIER® industrial firetube boiler is produced against a companywide “Concept to Completion” credo that exists from project inception through to boiler commissioning and start-up. Our manufacturing facilities are equipped to deliver on the diversity of firetube applications across multiple industries.

Our firetube team works seamlessly from in-house engineering and project management on through to manufacturing, logistics and field service to deliver a flawless product. Victory Energy controls the quality and timeliness on all project engagements to ensure that the product arrives on time and on budget.

Victory Energy FRONTIER® Dryback firetube boilers are available in virtually every size to meet board range of applications requirements.

PROPRIETARY DRYBACK BOILER FEATURES:

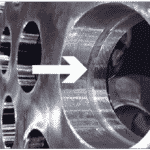

- Center Fired Design – Unique to Victory Energy Dryback firetube boilers feature a center fired design, promoting even distribution of heat in the rear tube sheet. Additionally, it provides enhanced interior water circulation.

- Stainless Steel Jacket – All Victory Energy firetube boilers include a heavy gauge stainless steel jacket.

- Easy-to-open rear access doors – The 3-pass design utilizes individual compartment doors at all flue gas turn spaces, to assure that flue gases contact all heating surface areas while proper heat release is maintained throughout the boiler.

- Advanced Refractory Technology – A special refractory utilized by Victory Energy has an expansion modulus of 0.00, from ambient to over 3,000 degrees, making the rear door impervious to expansion stress cracking, unlike our competitors. Non-spalling material makes it ideal for heavy oil applications.

- Serrated Tube Holes – all tube holes feature a serrated groove to maximize a solid, pressure tight seal of tubes to tube sheet.

The Frontier firetube product line includes 2, 3 and 4-pass designs. The 2 and 3-pass designs range up to 2,500 HP. The 4-pass design ranges up to 1,500 HP.

WASTE HEAT FIRETUBE BOILERS

Victory Energy offers a full range of HORIZON® Series firetube heat recovery boiler systems to meet the wide cross section of process heat recovery project requirements – from

sub-critical to the most demanding industry applications.

CAPACITIES

- Up to 100,000+ PPH

- Pressures range up to 800 PSIG

- Saturated

HRSG HEAT RECOVERY

Powerhouse Combustion & Mechanical Corporation proudly offers the complete line of Victory Energy Heat Recovery Steam Generation Products.

Recovering waste heat or using it for alternative system applications helps reduce costs and lessen the overall environmental impact. Victory Energy offers a multitude of heat recovery solutions to meet virtually every conceivable heat recovery application requirement. We’re constantly looking for ways to maximize the efficiencies and value of total integration for our customers and end users with rock-solid solutions that are reliable and compliant with the most stringent technical requirements.

Victory Energy produces a full range of custom-designed HRSG systems that are designed to deliver proven performance and crucial efficiencies at a cost effective price. Our heat recovery systems are, by design, engineered to be the most reliable steam generators in the world.

Our HORIZON® modular-designed units are completely shop-assembled to maximize transportation efficiencies and minimize field costs by lowering man hours needed for installation.

Additional benefits you can expect from a HORIZON Series HRSG:

- Module lifting lugs and temporary steel simplify field transport and handling

- Single wide, modular design

- 1, 2, or 3 pressure levels

- Full range of supplementary equipment

- Full shop assembled units or large assemblies are available industrial HRSGs for a variety of exhaust gases

- Modular assemblies simplify field labor and reduces construction costs

VICTORY ENERGY PLEDGE: Our sustainability pledge informs and drives our work through every action across all projects and engagements. At Victory Energy, we believe that the future of all energy must be based upon carbon reduction.

Our goal is to deliver more reliable, efficient and far cleaner energy solutions which truly impact the environment for today and future generations in the communities where we operate and live.

SUSTAINABILITY IS IN OUR POWER

GT-HRSG POWER UTILITY

Quality materials and superior construction is essential to producing heat recovery systems that are, by design, engineered to be the most reliable steam generators in the world. Our modular-designed units are completely shop-assembled to maximize transportation efficiencies and minimize field costs by lowering the man hours needed for installation.

COMBINED CYCLE / CHP UTILITY HRSG

The Victory Energy’s combined cycle and cogen utility type HRSGs are designed for operation with gas turbines in a multitude of applications.

Gas or oil-fired GTs, our HRSG HORIZON® Series can be configured to with multiple operating pressures, integral deaerator, saturated and/or superheated steam from 5,000 PPH up to 500,000 PPH in a single package or modularized system.

Our thermal performance modeling software is capable of accommodating a multitude of GTs and processes. All of our units are custom engineered and field verified. Shop assembly of each modular unit and component is maximized for efficient delivery and installation.

ADDITIONAL BENEFITS

- Fully shop assembled units or large assemblies are available for industrial HRSGs for a variety of exhaust gases

- Single wide, modular design

- Designs are custom engineered to accommodate transportation requirements

- 1, 2, or 3 pressure levels

- Full range of supplementary equipment

CAPACITIES

-

- Up to 120 MW

- Up to 500,000 PPH

- Pressure to 2,000 PSIG

- Steam Temperature up to 1,200°F

HEAT RECOVERY STEAM GENERATOR

Victory Energy’s industrial sized HORIZON® Series HRSGs are well suited for CHP in a diverse number of end markets.

Engineered with patented technologies, our systems are configured in a variety of arrangements to include diverter/by-pass stack, duct burners, CO catalyst & SCR.

Available from low capacity needs of 2,000 PPH to 200,000 PPH, (and larger capacities in our modular style units) 100 PSIG to 2,000 PSIG design pressure, and steam temperatures to 1,050 degrees F.

Quality materials and superior construction is essential to producing heat recovery systems that are, by design, engineered to be the most reliable steam generators in the world. Our approach to modularization is designed to maximize shop assembly while minimizing costly field labor and delivery time.

CAPACITIES

- Up to 200,000 PPH

- Pressures range up from to 2,000 PSIG

- Temperatures up to 1,200˚F

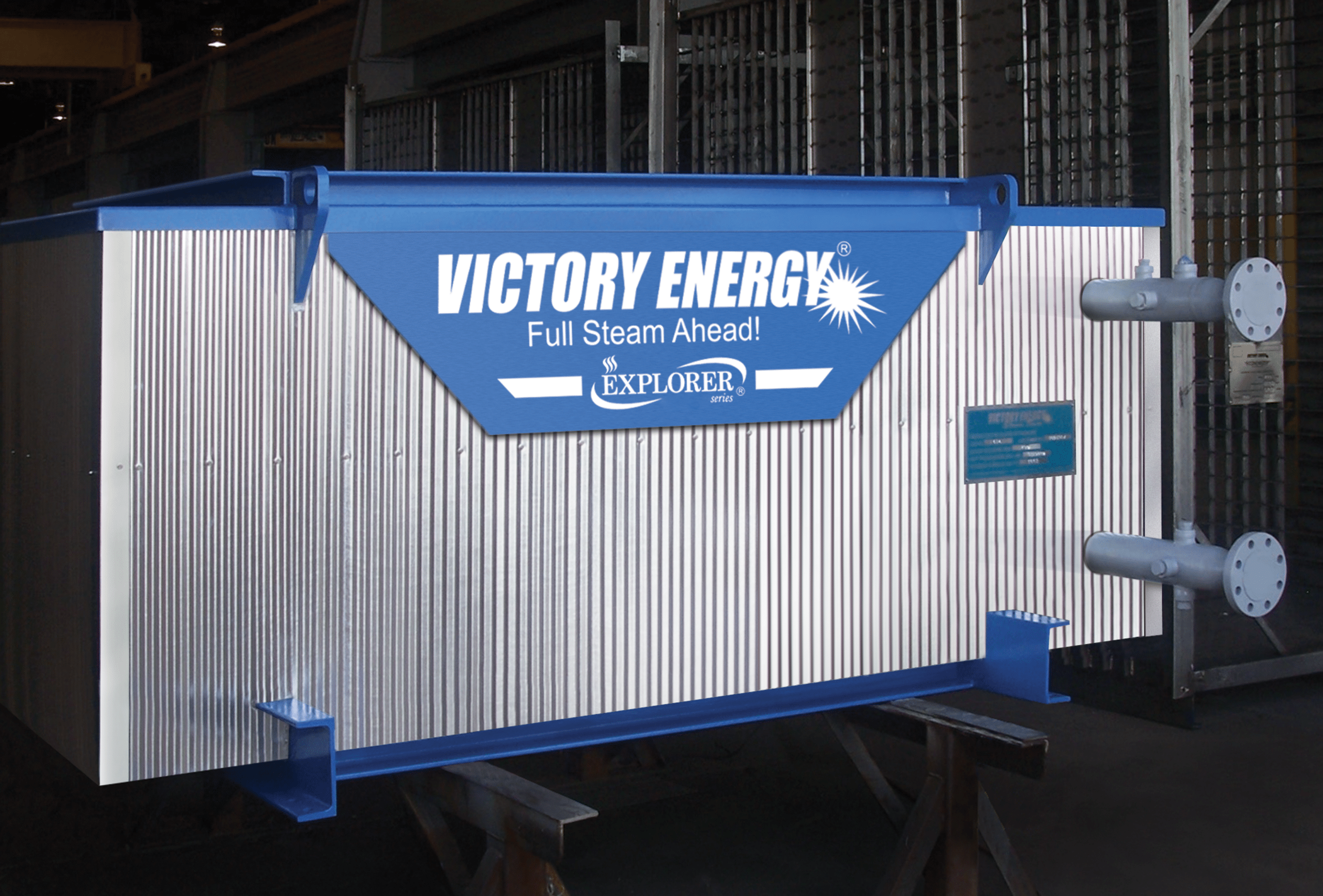

EXPLORER ECONOMIZER SERIES

Victory Energy offers heat recovery solutions for all your heat recovery needs. An EXPLORER® Series economizer from Victory Energy can “economize” your fuel usage by recovering energy that would otherwise be wasted.

Victory Energy’s EXPLORER® economizers are custom engineered for your application by our industry leading thermal design experts to maximize heat recovery. Every aspect of the economizer design is chosen with the aim of providing an economizer that will be in trouble-free service for many years.

From selecting the right metallurgy for the application, the right fin geometry and tube layout, based on fuel and fouling concerns, paying attention to erosion, corrosion and vibration concerns, you can rest assured that our EXPLORER economizer will be the optimum design for your application.

Our economizers are designed for economically optimum heat recovery with typical paybacks being in months, not years. Insulated and lagged with a gas tight casing, our economizers will be structurally engineered to handle any loads transmitted through your duct work, stack and structural steel accessory components.

APPLICATIONS

Victory Energy offers a complete suite of heat recovery products and accessories for all your applications, including:

- Boiler Feedwater Economizers / Rectangular / Cylindrical

- Condensing Economizers

- Waste Heat Oil Heaters

- Tubular Air Pre-heaters

- Liquid-Liquid heat exchangers

- Transitions, Stack, Support Steel, Controls, etc

CAPACITIES

- 100 BHP to greater than 1,000,000+ PPH

- Suitable for all fuel types

- Immediate payback

- Full condensing units available

HTHW GENERATOR

Powerhouse Combustion & Mechanical Corporation proudly offers the complete line of Victory Energy GENESIS HTHW Generation Products.

VICTORY ENERGY PLEDGE: Our sustainability pledge informs and drives our work through every action across all projects and engagements. At Victory Energy, we believe that the future of all energy must be based upon carbon reduction.

Our goal is to deliver more reliable, efficient and far cleaner energy solutions which truly impact the environment for today and future generations in the communities where we operate and live.

SUSTAINABILITY IS IN OUR POWER

INDUSTRIAL DUTY DESIGN

GENESIS hIGHT TEMPERATURE HOT WATER (HTHW) HEATER

GENESIS® High Temperature Hot Water (HTHW) Generators offer significant technological advances over competitive units in the market. The robust design features a complete membrane wall furnace that provides gas tight construction and maximum structural integrity while also minimizing any refractory.

It eliminates older tangent tube wall technology which in the past required manually adjustable orifices to properly distribute flow. The unit has the ability to handle high differential temperatures and eliminates hot spots in the generator by controlling flow evenly through the tubes with a weld gas tight seal.

GENESIS units come equipped with Victory Energy VISION® Burners that are low NOx and extremely fuel efficient.

CAPACITIES

- Output range – 5 MMbtu/hr to 200 MMbtu/hr

- Membrane wall design

- Low NOx burners

- Over size entry doors allow easy access

GENESIS HIGH TEMPERATURE THERMAL FLUID HEATER

GENESIS® High Temperature Thermal Fluid (HTTF) Heaters offer significant technological advances over competitive units in the market. GENESIS will heat any suitable range of thermal fluids. The robust design features a complete membrane wall furnace that provides gas tight construction and maximum structural integrity while also minimizing any refractory.

It eliminates older tangent tube wall technology which in the past required manually adjustable orifices to distribute flow. The unit has the ability to handle high differential temperatures and eliminates hot spots in the generator by controlling flow evenly through the tubes with a weld gas tight seal.

GENESIS units come equipped with Victory Energy VISION® Burners that are low NOx and extremely fuel efficient.

CAPACITIES

- Output range – 5 MMbtu/hr to 200 MMbtu/hr

- Membrane wall design

- Low NOx burners

- Over size entry doors allow easy access

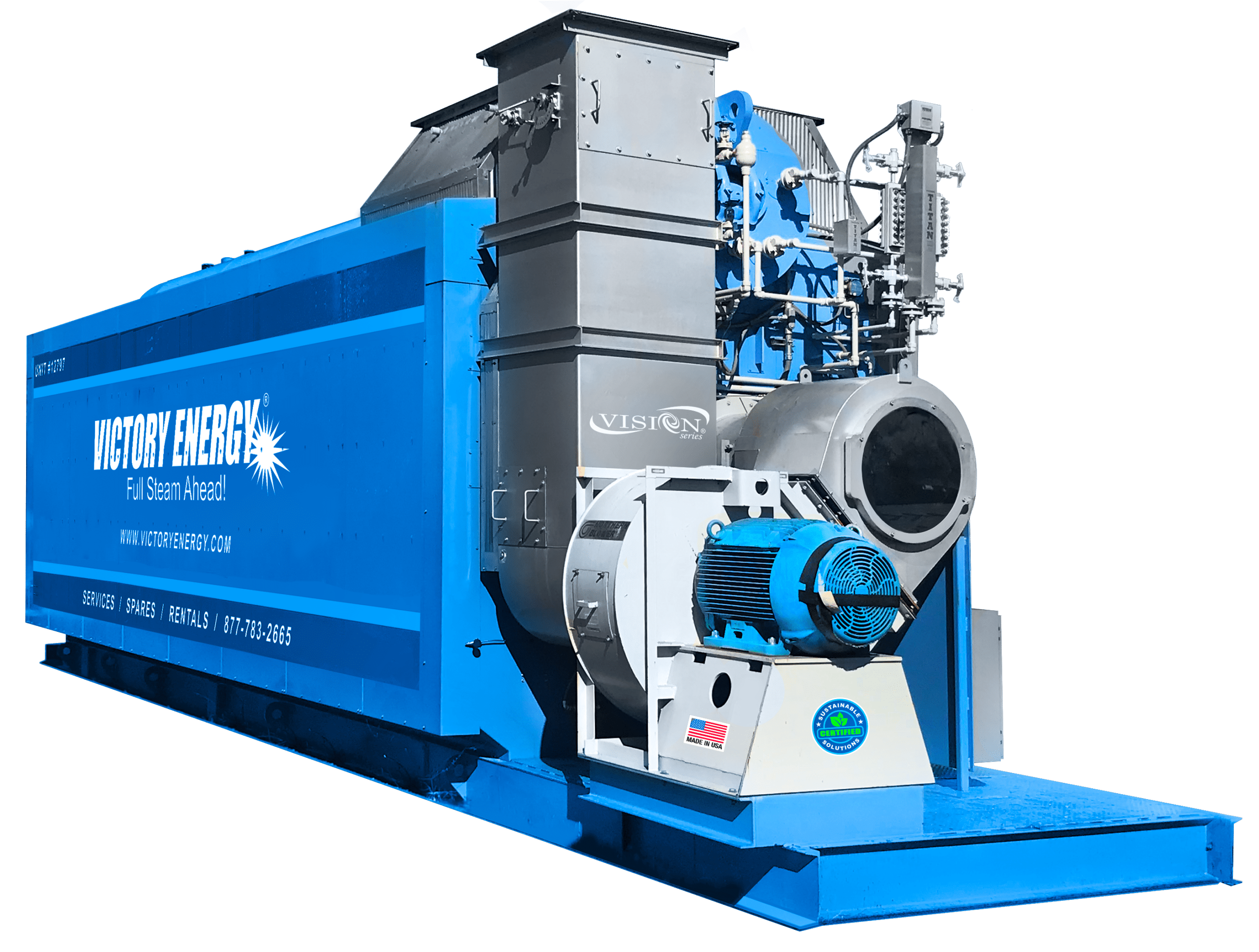

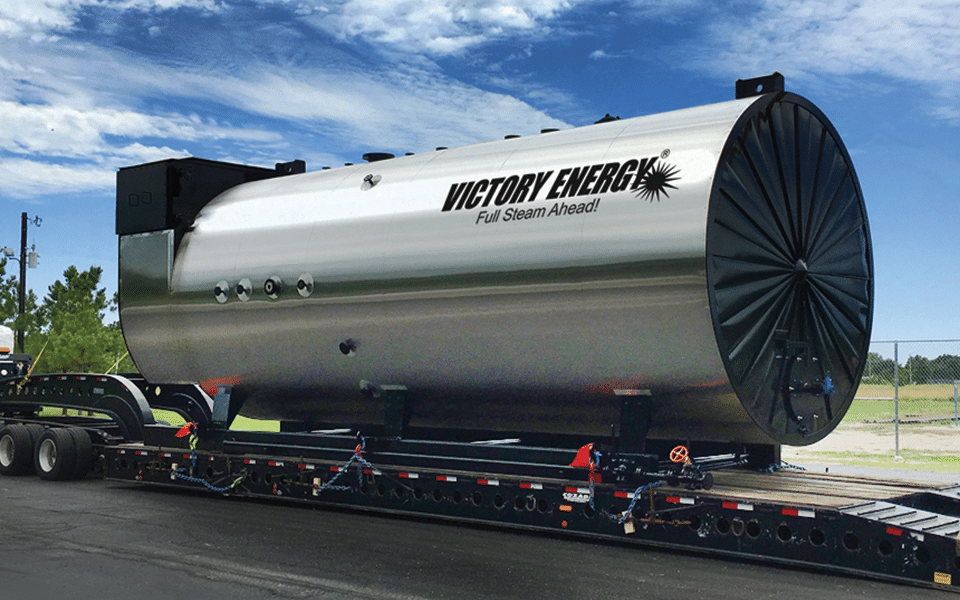

rENTAL BOILERS

Powerhouse Combustion & Mechanical Corporation proudly offers the complete line of Victory Energy products available for rental

Victory supplies cost-effective mobile boiler rental solutions for virtually any utility, institutional and industrial steam application. Our trailer-mounted boilers range in size from 40,000 lb./hr. to 150,000 lb./hr. with operating pressure from 100-750 psi. These units are mounted on customized, highway-legal trailers.

Our mobile boilers can be dispatched directly to a job site, quickly and safely. We provide 24-hour phone service and 24-hour boiler-technician dispatch. Upon arrival, there are no cranes or rigging required; no need for special handling to load or unload boilers at either the job site or the storage yard. As a result, you save time and money. Custom trailers facilitate the maneuverability of trailer-mounted boilers.

Because our mobile boiler systems are essentially self-contained, only connection to an electrical power source, fuel and water supplies, and a steam header are required for operation.

We also have the capability of providing mobile water treatment systems designed to operate with our rental boilers. Optional 75,000 PPH mobile water treatment systems include deaerators, water softeners, boiler feedwater pumps and a chemical treatment system, pre-piped and wired within a standard 53-foot over the road enclosed trailer.

Our equipment and services are available 24/7.

RENTAL UNITS ARE CRITICAL FOR:

- Unplanned Downtime

- Natural Disasters

- Retube of Existing Boiler

- Boiler Replacement

- Project Delays

Burners

Powerhouse Combustion & Mechanical Corporation proudly offers the complete line of Victory Energy Burner Products

Victory Energy manufactures industrial burner solutions delivered through a comprehensive line – the Pro Series product solutions. Our VISION® product portfolio is designed to meet virtually every burner application – new projects and retrofit.

VISION burners are essential core elements in the Victory Energy vertically integrated industrial burner and boiler solutions and our concept to completion promise.

The ability to design, manufacture and integrate both the steam generation and combustion systems in our Collinsville operation assures our customers overall system compatibility and single source responsibility. This approach offers a magnitude of difference in overall performance and sustainability gains for your operation.

VICTORY ENERGY PLEDGE: Our sustainability pledge informs and drives our work through every action across all projects and engagements. At Victory Energy, we believe that the future of all energy must be based upon carbon reduction.

Our goal is to deliver more reliable, efficient and far cleaner energy solutions which truly impact the environment for today and future generations in the communities where we operate and live.

POWER UP WITH THE BENEFITS OF SUSTAINABLE SOLUTIONS

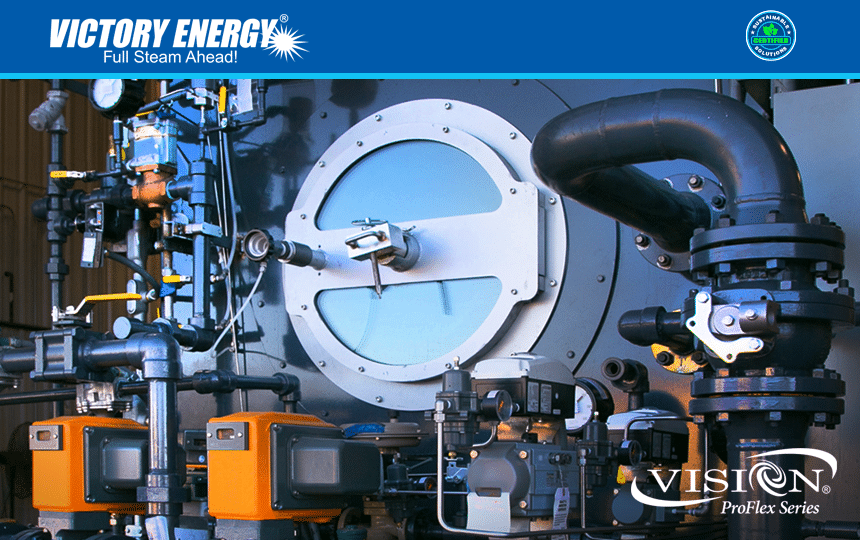

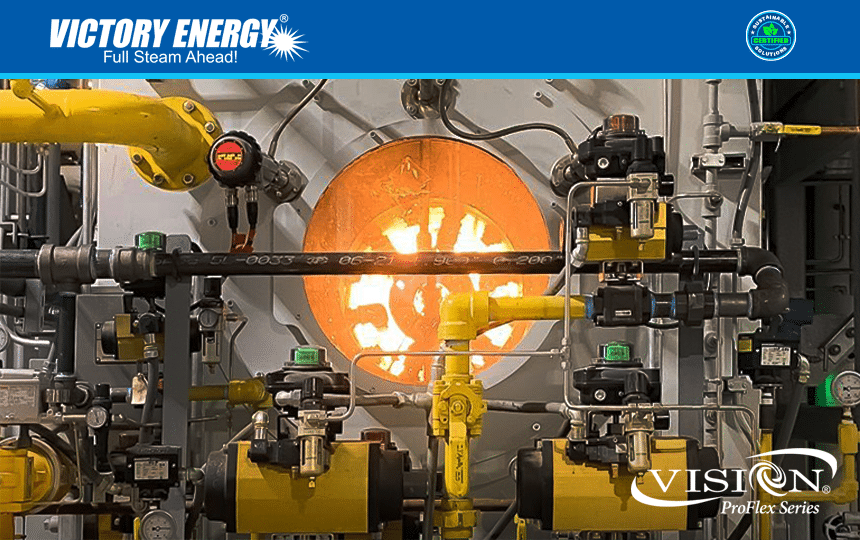

VISION PROFLEX SERIES

INDUSTRIAL DUTY DESIGN

SINGLE-SOURCE SOLUTIONS

Victory Energy’s ability to design, engineer, manufacture and integrate the combustion systems in combination with the steam generation requirements are unique. The benefits of working with a single source for the entire burner and boiler system will enhance efficiencies and maintenance practices.

VISION® ProFlex industrial burners provide the best emissions reduction metrics. They’re an integral component of the Victory Energy Sustainable Solutions promise. The product line is comprised of 6 model sizes that deliver the widest range of low NOx emissions performance to meet the most stringent sustainability application challenges.

The complete line of VISION ProFlex burners combined with the proven line of Victory Energy industrial boilers and hot water generators deliver a vertically integrated package that is unmatched in the boiler industry.

The VISION Burner technology ensures complete and efficient combustion with very low emissions; < 30 ppm NOx with little or no FGR. This sturdy and simple design translates into high reliability and low maintenance. The VISION ProFlex Series Burner can be applied to both single and multi-burner boilers.

Numerical fluid flow simulation tools were used during the design of the VISION ProFlex Series Burner , allowing the traditional windbox to be replaced by strategically placed baffles and openings between the fan and the burner throat, making the burner very compact and efficient.

The large glass VISION ProFlex Series Door allows for a safe visual inspection during burner operation, providing an unprecedented level of visual insight into the core of the flame as well as the furnace.

IDEAL FOR RETROFIT APPLICATIONS AND NEW INSTALLMENTS.

VISION ProFlex SERIES BURNER

- Robust Industrial Style Burner

- Engineered-To-Order

- 6 Sizes – 30 MMBtu/hr to 500 MMBtu/hr

- <9 ppm NOx – Gas

- <75 ppm NOx – Oil

- Low CO2, CO & VOC & PM

- Excellent Fuel Turn Down: 20:1 Gas & 8:1 Oil

- Heat Input Based on 70° F Air and 1000’ Elevation

- Gas and/or Oil Fuel Firing Capability

VISION ProFlex SERIES DOOR

- Large viewport

- Unparalleled visual inspection of the flame core

- Furnace Access door

SPARKMAX IGNITER

- Standard Equipment

- NFPA CLASS 1, 2 OR 3 GAS IGNITER

– Capacity ranges from 0,25 MMBtu/hr to 40 MMBtu/hr

– Standard to severe-duty environments

– 99% ignition rate in most applications

– Highly reliable ignition enhanced by quick Premix Combustion

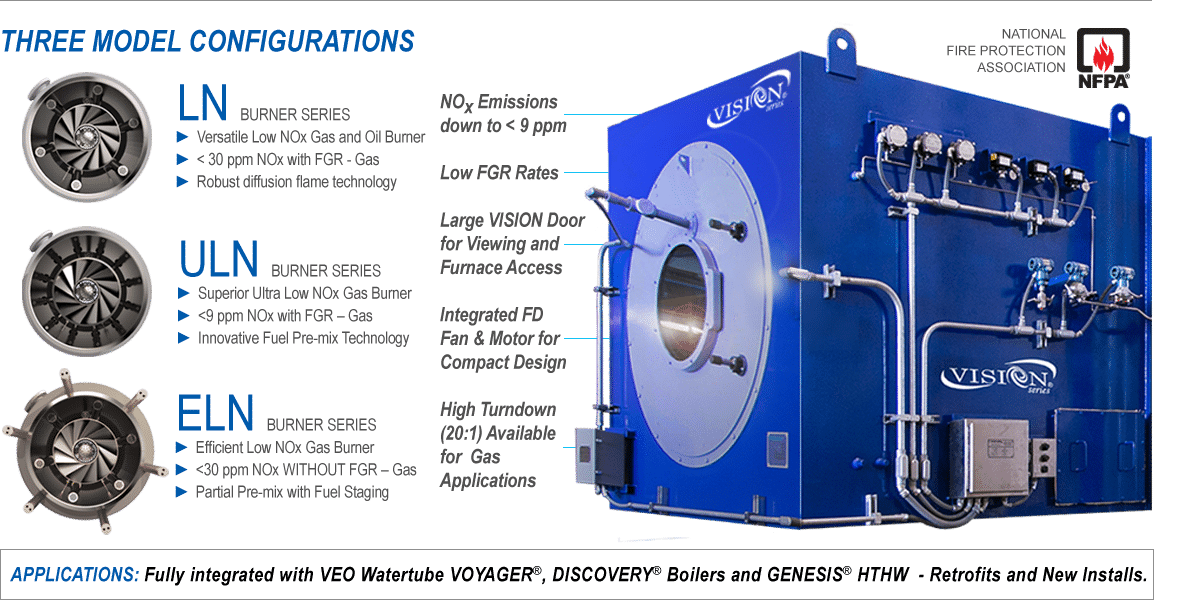

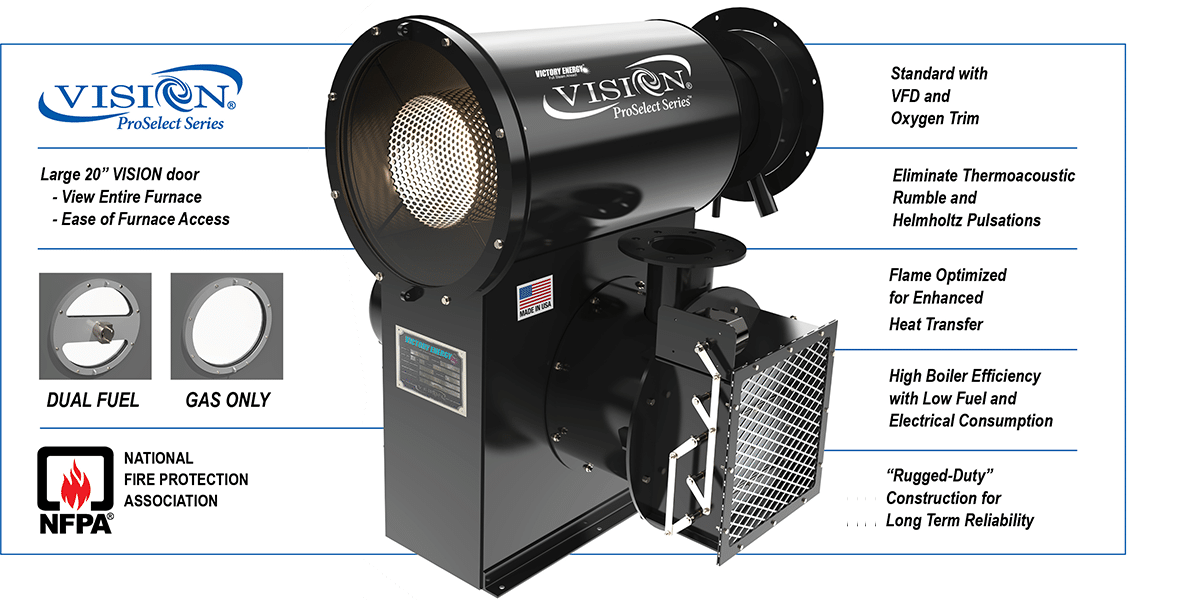

VISION PROSELECT SERIES BURNER

SINGLE SOURCE SOLUTIONS

VISION® ProSelect burners provide outstanding emissions reduction metrics. They’re an integral component of the Victory Energy Sustainable Solutions promise. There are 7 models across a deep product offering that deliver a wide range of low NOx / ultra-low NOx emissions performance that meet the toughest sustainability application challenges.

Victory Energy’s ability to design, engineer, manufacture and integrate the combustion systems in combination with the steam generation requirements are unique. The benefits of working with a single source for the entire burner and boiler system will enhance efficiencies and maintenance practices.

The complete line of VISION ProSelect burners in tandem with the proven line of Victory Energy Firetube boilers deliver a vertically integrated package that is setting new standards in the boiler industry.

IDEAL FOR RETROFIT APPLICATIONS AND NEW INSTALLMENTS.

VISION ProSelect SERIES BURNER

- Standardized Design Selection

- 100 HP to 2500 HP Capacity

- 7 Models / Packages

- <9 ppm NOx with FGR – Gas

- <30 ppm NOx with FGR – Gas

- <75 ppm NOx with FGR – Oil

- Low CO2, CO, VOC and PM

- High Fuel Turn Down with High Efficiency

– Gas: 10.1

– Oil: 8.1

VISION ProSelect SERIES DOOR

- Large viewport

- Unparalleled Visual Inspection of the Flame Core

- Furnace Access door

SPARKMAX IGNITER

- Standard Equipment

- NFPA CLASS 1, 2 OR 3 GAS IGNITER

– Capacity ranges from 0,25 MMBtu/hr to 40 MMBtu/hr

– Standard to severe-duty environments

– 99% ignition rate in most applications

– Highly reliable ignition enhanced by quick Premix Combustion

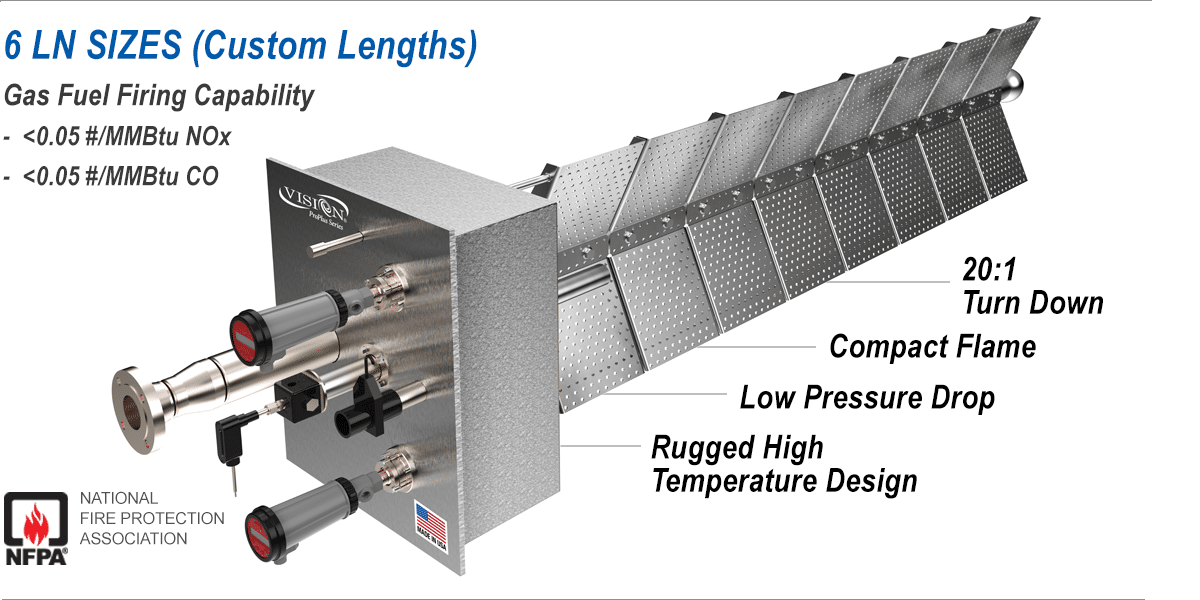

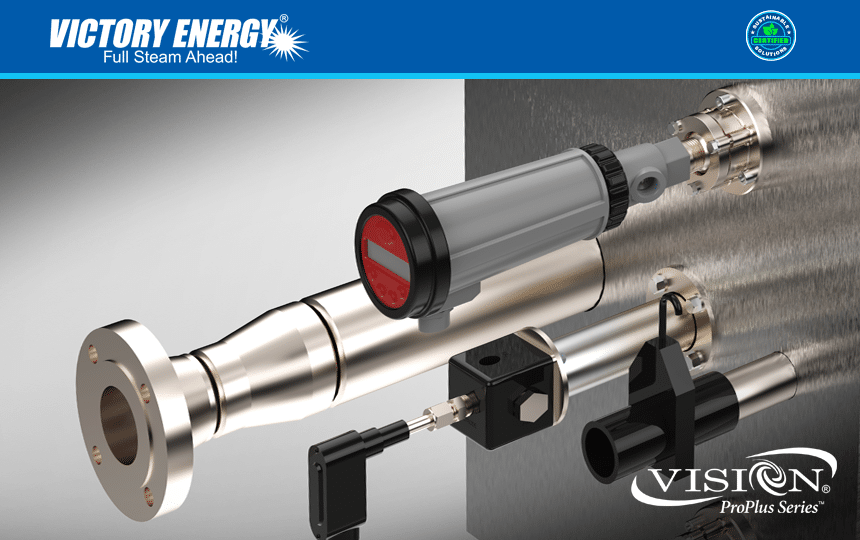

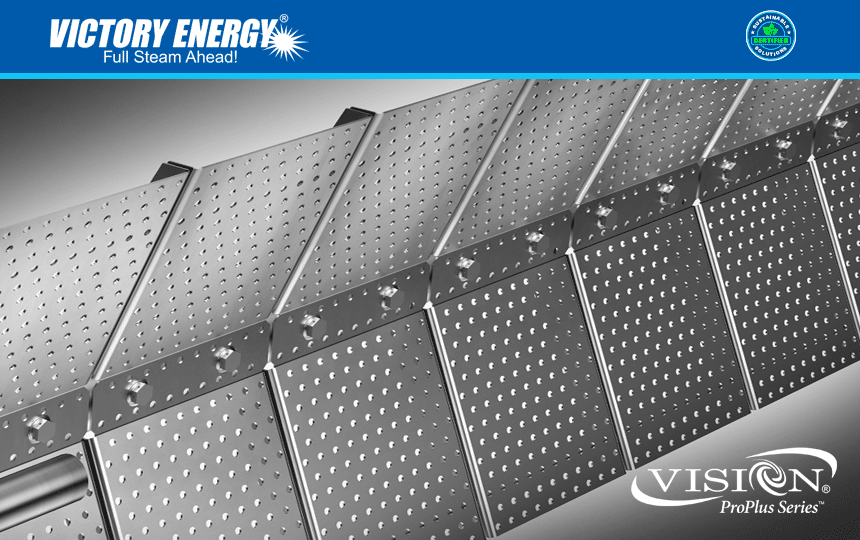

VISION PROPLUS SERIES BURNER

ENGINEERED-TO-ORDER

VISION® ProPlus Duct Burners provide the best emissions reduction metrics. They’re an integral component of the Victory Energy Sustainable Solutions promise. The product line is comprised of 6 models that deliver the widest range of low NOx emissions performance to meet the most stringent sustainability application challenges.

Victory Energy’s ability to design, engineer, manufacture and integrate the combustion systems in combination with the steam generation requirements are unique. The benefits of working with a single source for the entire burner and boiler system will enhance efficiencies and maintenance practices.

The complete line of VISION ProPlus Duct Burners combined with the proven line of Victory Energy Heat Recovery Steam Generators deliver a vertically integrated package that is unmatched in the boiler industry.

The VISION Burner technology ensures complete and efficient combustion with very low NOx, CO, VOC and PM emissions. This sturdy and simple design translates into high reliability and low maintenance.

IDEAL FOR RETROFIT APPLICATIONS AND NEW INSTALLMENTS.

BURNER

- Robust Industrial Style Burner

- Engineered-To-Order

- Billion BTU/hr Capacity

- 6 Models

- Low Emissions – NOx, CO, VOC and PM

- Excellent Temperature Distribution

- Low Pressure Drop

SPARKMAX IGNITER

- Standard Equipment

- NFPA CLASS 1, 2 OR 3 GAS IGNITER

– Capacity ranges from 0,25 MMBtu/hr to 40 MMBtu/hr

– Standard to severe-duty environments

– 99% ignition rate in most applications

– Highly reliable ignition enhanced by quick Premix Combustion

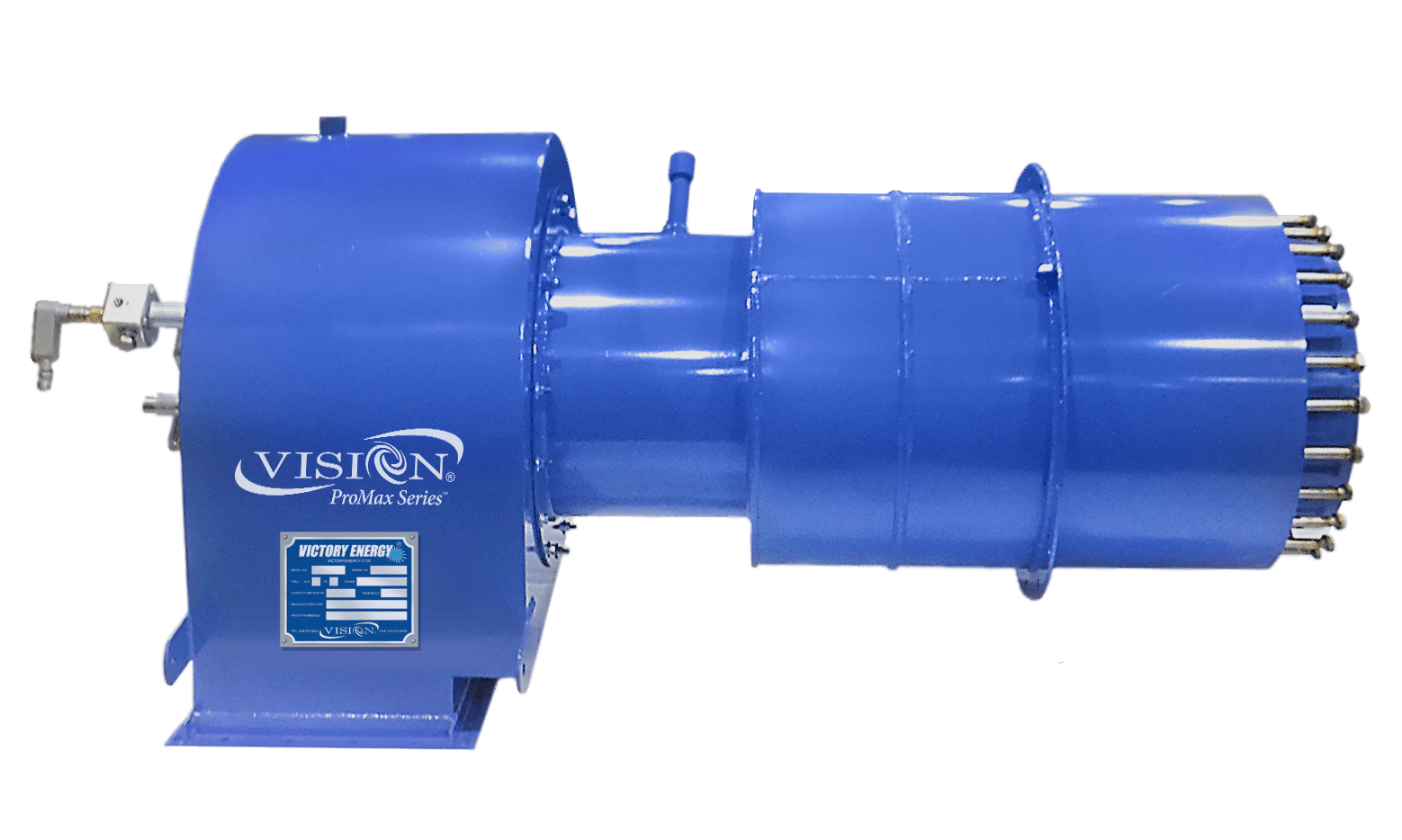

VISION PROMAX SERIES BURNER

SINGLE-SOURCE SOLUTIONS

Victory Energy’s ability to design, engineer, manufacture and integrate the combustion systems in combination with the steam generation requirements are unique. The benefits of working with a single source for the entire burner and boiler system will enhance efficiencies and maintenance practices.

VISION Promax Series Burners provide the best emissions reduction metrics. They’re an integral component of the Victory Energy Sustainable Solutions promise. The product line is comprised of 12 model sizes that deliver the widest range of low NOx emissions performance to meet the most stringent sustainability application challenges.

The complete line of VISION ProMax Series Burners combined with the proven line of Victory Energy industrial boilers and hot water generators deliver a vertically integrated package that is unmatched in the boiler industry.

The VISION Burner technology ensures complete and efficient combustion with very low emissions; < 30 ppm NOx with little or no FGR. This sturdy and simple design translates into high reliability and low maintenance. The VISION ProMax Series Burner can be applied to both single and multi-burner boilers.

Numerical fluid flow simulation tools were used during the design of the VISION ProMax Series Burner , allowing the traditional windbox to be replaced by strategically placed baffles and openings between the fan and the burner throat, making the burner very compact and efficient.

The large glass VISION ProMax Series Door allows for a safe visual inspection during burner operation, providing an unprecedented level of visual insight into the core of the flame as well as the furnace.

IDEAL FOR RETROFIT APPLICATIONS AND NEW INSTALLMENTS.

VISION ProMax SERIES BURNER

- Standardized Designs

- 12 Model Sizes

- 30 MMBtu/hr to 425 MMBtu/hr

- High Combustion Efficiency

- Improved Process Throughout

- Low Maintenance

VISION ProMax SERIES DOOR

- Large viewport

- Unparalleled visual inspection of the flame core

- Furnace Access door

SPARKMAX IGNITER

- Standard Equipment

- NFPA CLASS 1, 2 OR 3 GAS IGNITER

– Capacity ranges from 0,25 MMBtu/hr to 40 MMBtu/hr

– Standard to severe-duty environments

– 99% ignition rate in most applications

– Highly reliable ignition enhanced by quick Premix Combustion

Download General Information

Click the links below for some important product data and more details on the key features.